Case Study:

Foam Seat

Manufacturer

1 Introduction

2 Tracking: Production Line

3 Tracking: Supply Chain

4 System Architecture

5 Goals Achieved

Introduction

This case study describes the RFID project for a foam car seat manufacturer based in the North of

England. The manufacturer faced a problem in tracking their product through the production line as

well as along the supply chain. We developed and set up an RFID system that tagged and tracked the

product, allowing the manufacturer to know:

1. When the product was created

2. When the product passed specific points along the production line,

3. When it was shipped out to the customer and

4. When the customer received it at their Goods In.

Objectives

The company's objectives were:

1. To have real time tracking of individual items along the production line

2. To have live snapshot information of the status of all items in production

3. To have historical information of all items that have been manufactured, and the specific toolset

that was used in the manufacture of each individual item

4. To implement checks and controls during the movement of goods along the supply chain

Tracking along the Production Line

RFID tags in the product helps to

track the item along the various

stages of the Production Line

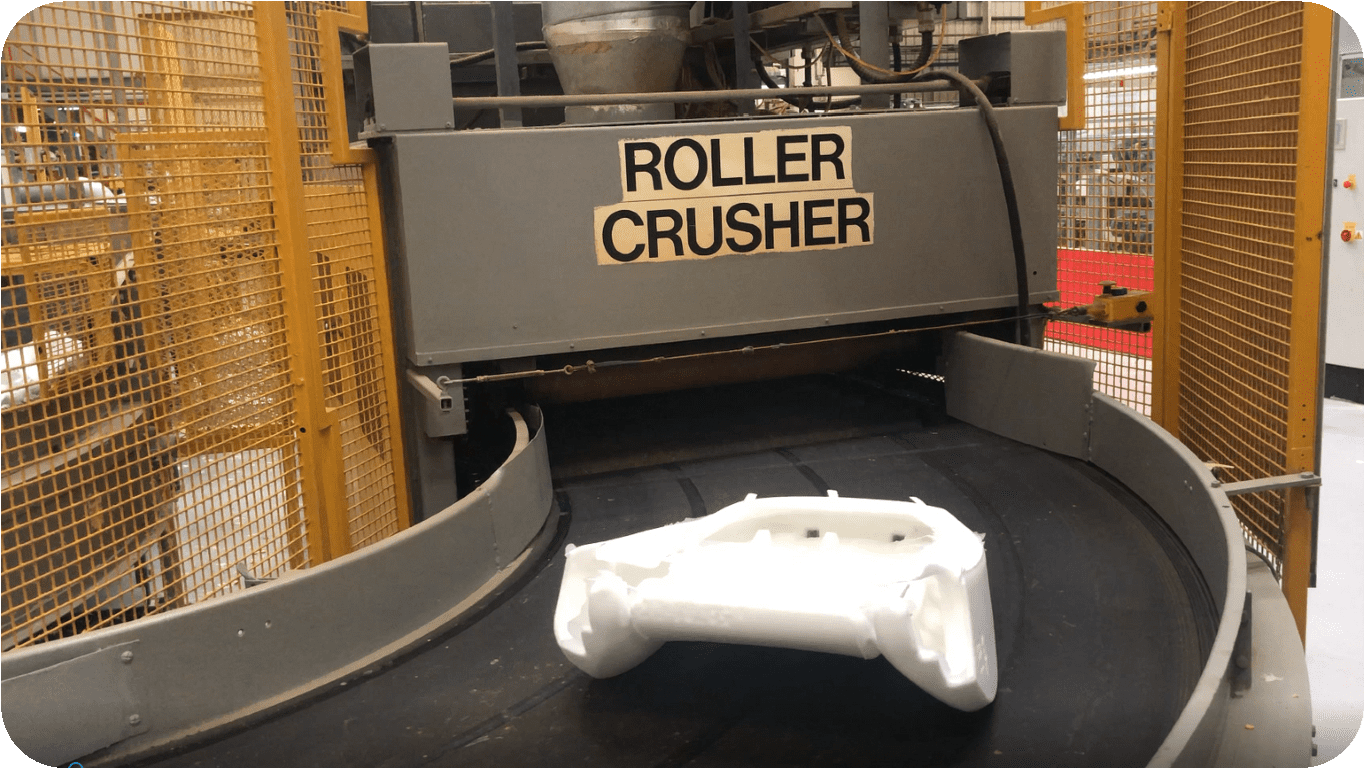

The company creates foam seats using specific moulds for specific seat types and these are added

to a production line which circles round from a start point to an end point. The moulds are filled at

the start point in the production line and the completed foam seats are removed after successful

processing.

We produced software that manages the encoding and verification of production line tags. An

embedded tag, termed an Inset Tag, is embedded into the foam seats at the start point of the

manufacture. Information about each specific tool used is written onto the embedded tag every time

the tag passes a tool. This allows the traceability of which tool was used at each stage of production

to produce the product. The tool tag data also includes a timestamp which allows for auditing and

tracking of the Inset Tag.

Tracking along the Supply Chain

GoodsOut at Manufacturer's Site

The company also wished to track their products as they moved out from their warehouse, and

throughout the journey as they were bring received in the Goods In of their customer's site. The

objective here was to ensure that no goods were lost in transit, and to ensure that any seats that did

not meet customer satisfaction could be traced to a specific production line and tool set.

This was implemented using an RFID fixed portal scanning system which

facilitated the tracking of production items moving from the production area

out to the warehouse. The foam seats were packed in plastic crates/boxes,

with a single box to contain between 40 and 42 seats. As each seat had one

tag, if less than 40 or more than 42 tags were read, this would be flagged as an

error and trigger a visual alarm (red light) and a warning noise via a sounder.

The RFID tags also included information about the product group, and all the

items in a crate had to have the same product code. In the event this was not

true the visual alarm would be triggered. If no errors were encountered a green

light would flash silently.

GoodsOut at Manufacturer's Site

An RFID fixed portal scanning system was also installed at Goods In at the Customer's site. This

allowed for the crates that were sent to the customer to be scanned on receipt, and any loss during

transit to be recorded at the point at which the crates are received by the customer.

As the seats were unpacked and picked up for further processing, any seat that did not meet the

customer satisfaction could be marked as such. The tag would be read and the details of the entire life

of that individual seat from the point of creation, to the list of each and every tool that was used in the

production of that seat would be displayed. This allowed for quicker identification of problems such as

deteriorating moulds along the production line.

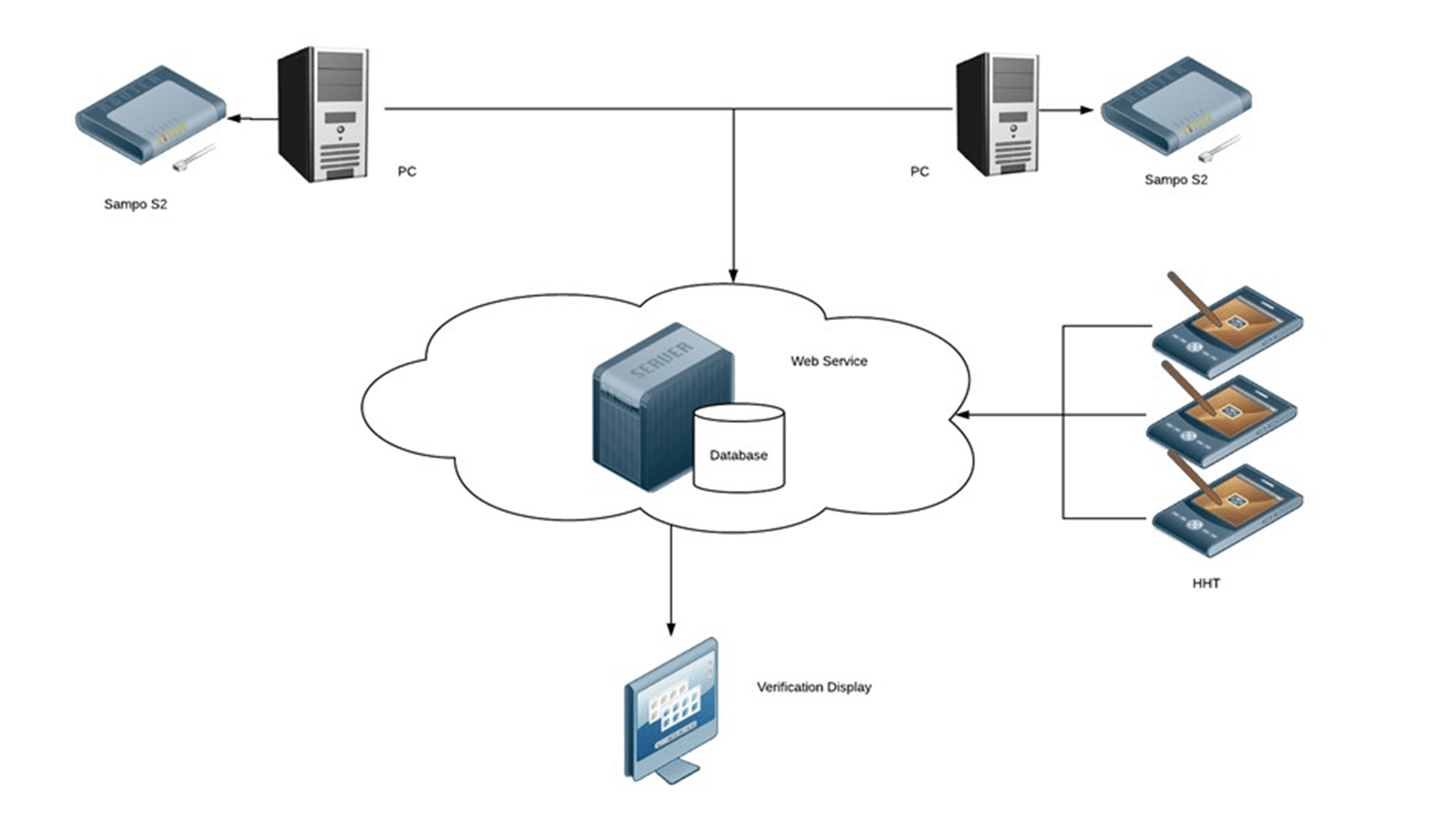

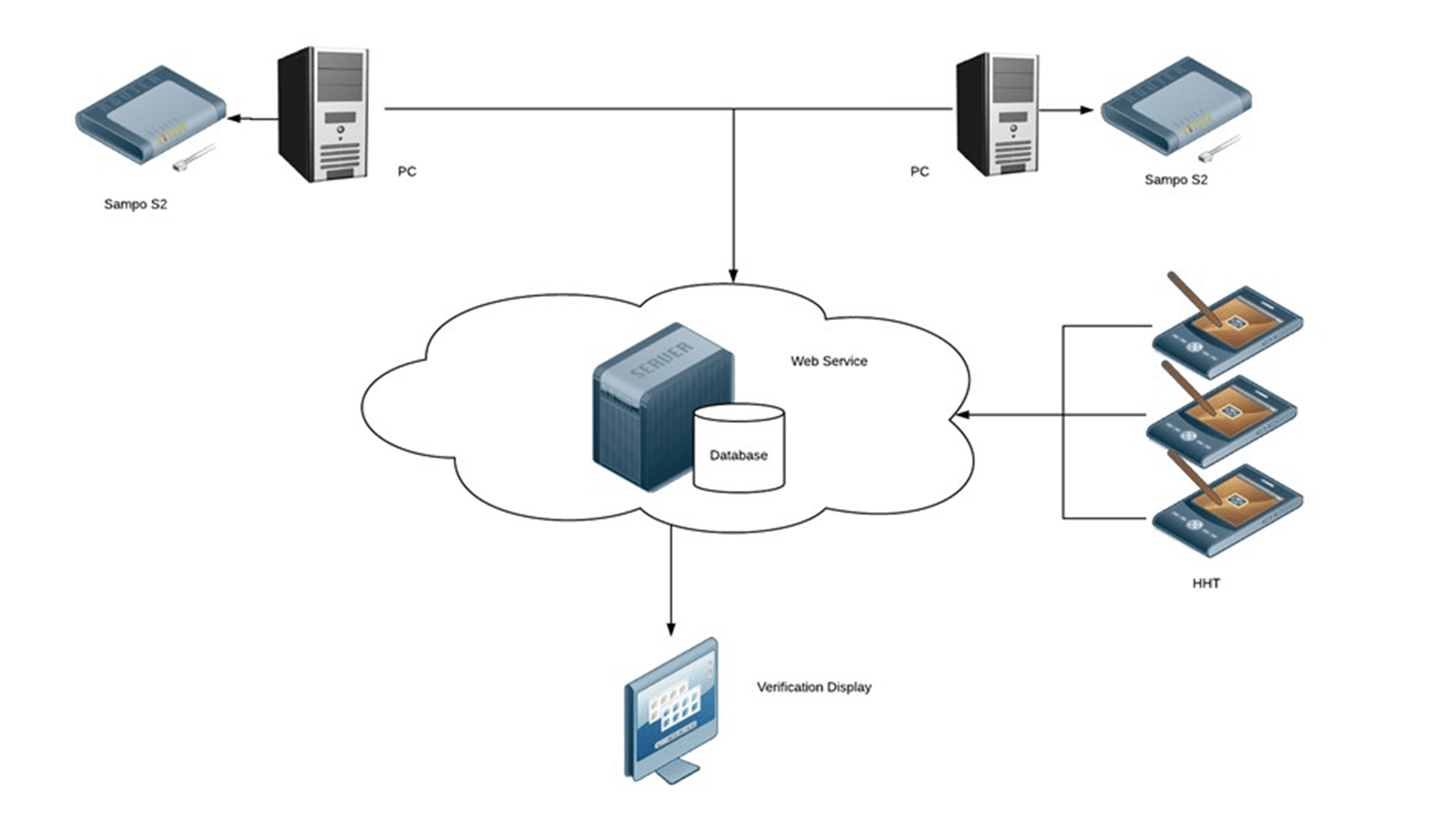

System Architecture

Technology Stack

The system depicted above provides a logical view of the various components. In the case of

using USB connected Sampo Readers, each reader will need to be connected directly to a single

PC. One PC will form the Encoding Station to encode the tags and have the appropriate software

for this purpose and the second PC will be set up as the Verification station.

In addition both the Verification and Encoding software application make use of a Web Service

which is in turn attached to a single SQL Database. This Web Service provides a simple RESTful

API to enable the two stations to record and retrieve the tag information.

This Web Service can be hosted on a third, separate PC or on a cloud.

Goal Achieved

100%

Journey of products tracked from creation to the point at which customer satisfaction was recorded

The RFID tracking system:

• Provided the manufacturer with real time information about the production.

This helped them to take proactive steps as necessary to achieve the Just In

Time manufacturing goals.

• Allowed them to identify tool sets that were wearing out, and goods lost or

damaged during shipment to their customer site.

Key challenges overcome:

• Ensuring the accuracy of RFID tags being read, without reading adjacent tags

in error

• Accurately identifying and mapping the process flow in case of error

conditions