RFID COLD STORAGE

INVENTORY

MANAGEMENT

Move away from Paper-Based Records

The

Problem

The company needed to record locations where their stock are stored, and to

have a system that allows efficient stock rotation to eliminate wasted stock.

The Solution

Nexatrak's Stokware Asset Tracking solution was an ideal choice as it

allowed BBP to create rails and add dolavs using a very user friendly web

front end. Stokware also allowed for the contents of each dolav to be

recorded. Every dolav was tagged, and its rail location recorded.

• Stokware's picking algorithm allowed personnel to always pick the

product that has the most recent expiry date, thus enabling

efficient stock rotation

• Stokware's put away algorithm allowed for products to be

stored based on their expiry dates , thus ensuring that the picking

process is optimised in terms of time taken

• Stock location is updated automatically

• The Stokware mobile app with handheld Zebra RFID readers also

allowed for personnel to record product temperatures

• Detailed audit logs show full movement records of each dolav

• Nexatrak customised Stokware to support BBP business processes

Benefits Realised

Improved Inventory Control

The company always had up to date information at their fingertips.

Eliminated Loss of Inventory due to Inefficient Stock Rotation

The directed picking meant that stock with most recent expiry dates was always picked first, thus

eliminating losses arising due to expired products going unpicked.

Reduced Manhours Labour Intensive Processes

Labour intensive processes such as putting stock away and picking stock for slicing was made

efficient as personnel no longer needed to "search" for stock.

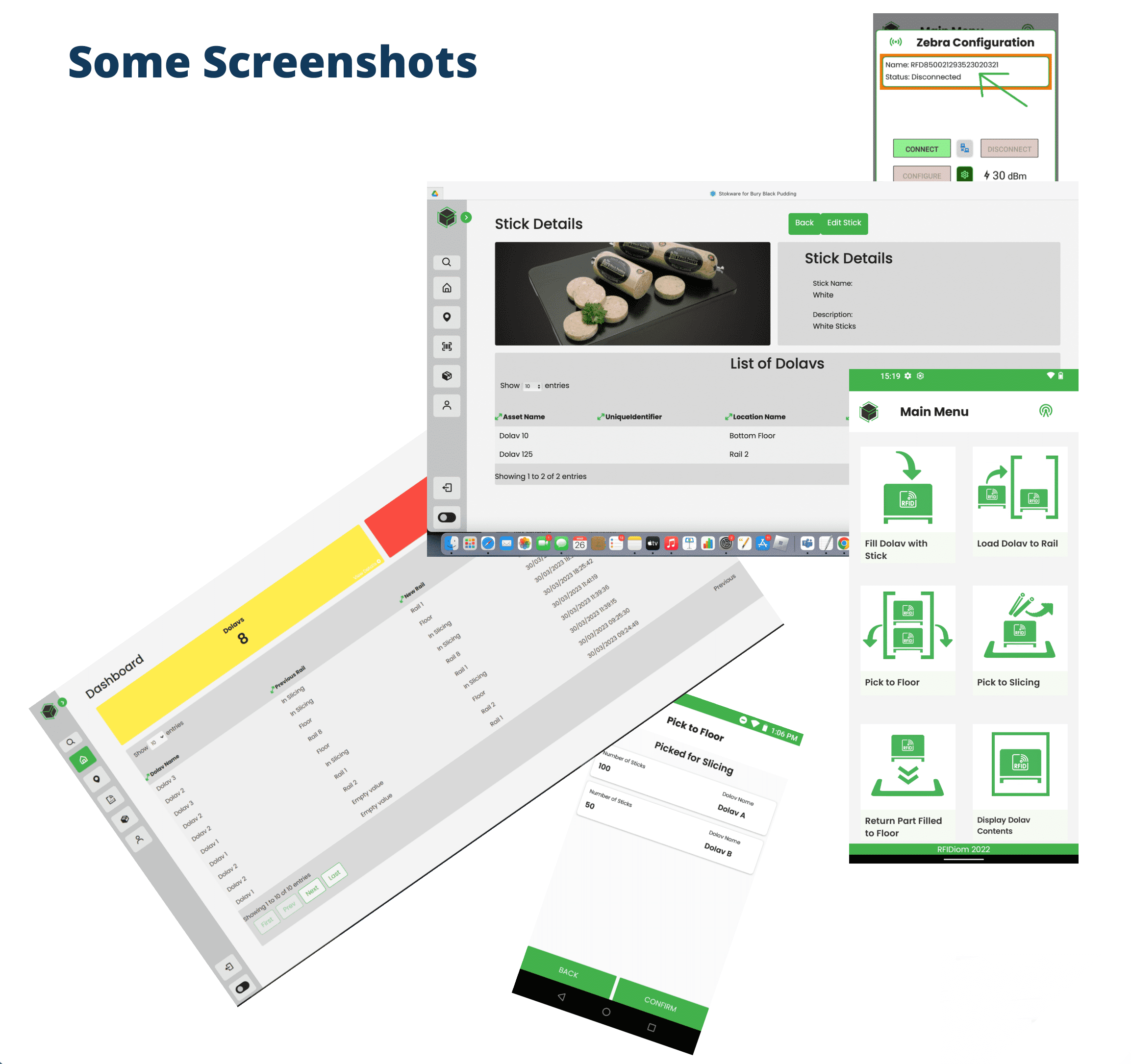

Some Screenshots

The Solution

Nexatrak's Stokware Asset Tracking solution was an ideal choice as it

allowed BBP to create rails and add dolavs using a very user friendly web

front end. Stokware also allowed for the contents of each dolav to be

recorded. Every dolav was tagged, and its rail location recorded.

• Stokware's picking algorithm allowed personnel to always pick the

product that has the most recent expiry date, thus enabling

efficient stock rotation

• Stokware's put away algorithm allowed for products to be

stored based on their expiry dates , thus ensuring that the picking

process is optimised in terms of time taken

• Stock location is updated automatically

• The Stokware mobile app with handheld Zebra RFID readers also

allowed for personnel to record product temperatures

• Detailed audit logs show full movement records of each dolav

• Nexatrak customised Stokware to support BBP business processes

Benefits Realised

Improved Inventory Control

The company always had up to date information at their fingertips.

Eliminated Loss of Inventory due to Inefficient Stock Rotation

The directed picking meant that stock with most recent expiry dates was always picked first, thus eliminating losses arising due to expired products going unpicked.

Reduced Manhours Labour Intensive Processes

Labour intensive processes such as putting stock away and picking stock for slicing was made efficient as personnel no longer needed to "search" for stock. Some Screenshots